The hydraulic fracturing industry is focusing on innovations to minimize fuel consumption, simplify equipment, and automate tasks. This drive is resulting in increased horsepower density, fewer personnel required for well completion, lower operating costs, reduced safety risks, community impacts, and emissions. Vertical integration has aided in-house manufacturing, mitigating the impacts of global supply chain disruptions. Many new pressure pumping fleets are being built as electric or dual-fuel fleets to displace diesel with natural gas, leading to substantial savings in fuel costs and emissions. Industry players are becoming more disciplined in response to demand for pressure pumping services, leading to careful consideration of capacity expansion.

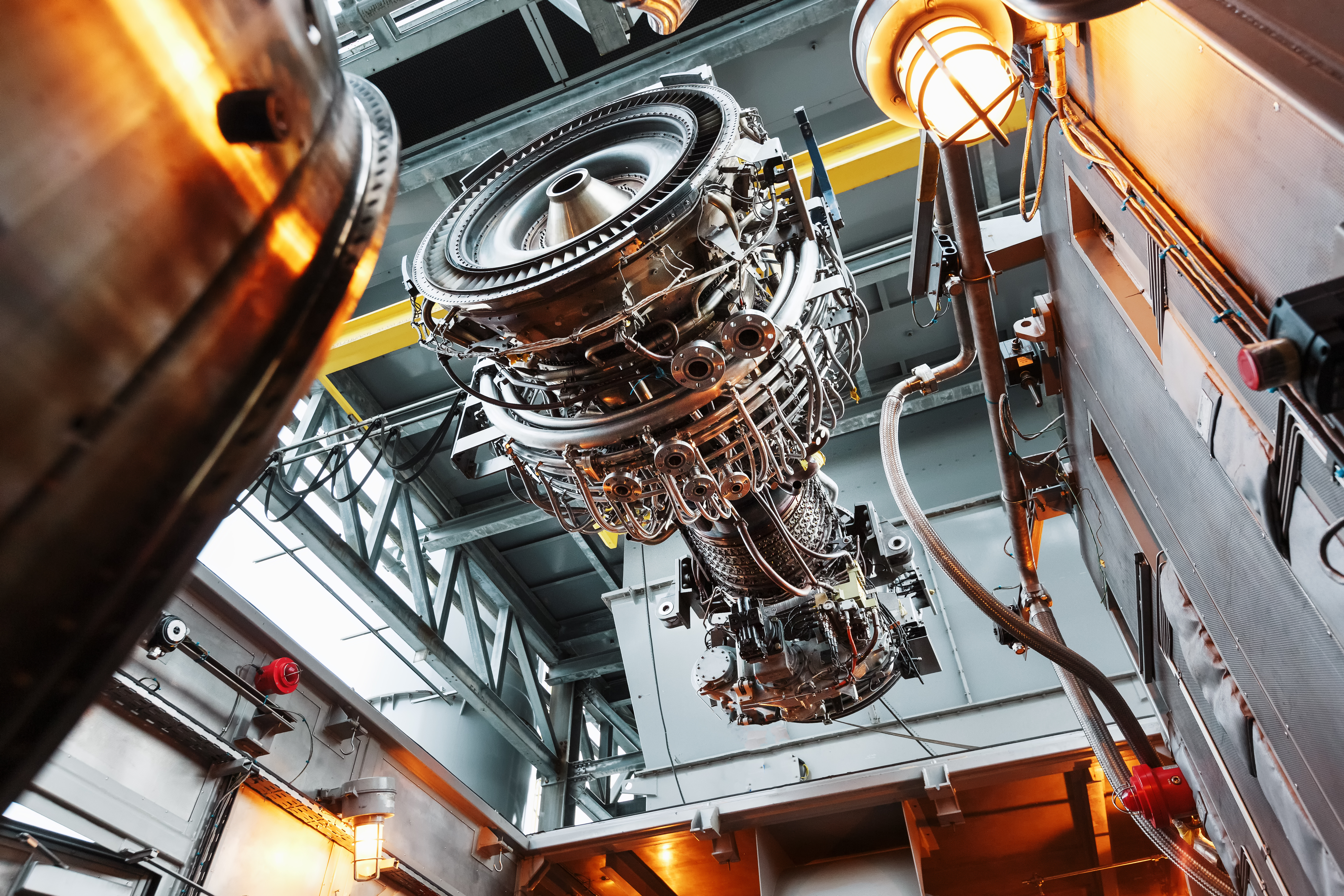

Continental Controls Corp. has introduced smart fuel valves that adjust fuel mix to variations in gas quality, enhancing turbine efficiency, stability, and emissions reduction. These valves can be retrofitted onto existing turbines, enabling cost-effective upgrades. Overall, the industry is embracing technology and innovation to address environmental concerns, boost efficiency, and reduce costs in hydraulic fracturing operations.