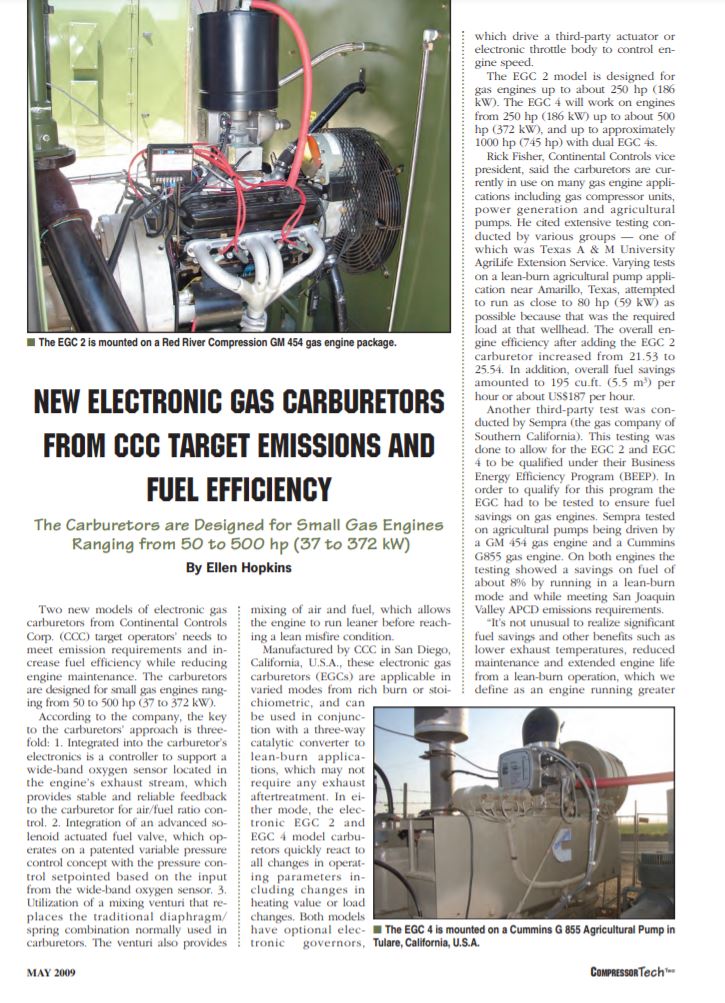

There are two innovative models of electronic gas carburetors at Continental Controls Corporation aimed at small gas engines (ranging from 50 to 500 hp). These carburetors are engineered to meet stringent emissions requirements, optimize fuel efficiency, and minimize the need for engine maintenance. The distinctive approach of these carburetors revolves around three fundamental aspects. First, they incorporate a controller connected to a wide-band oxygen sensor positioned in the engine's exhaust stream, ensuring a stable and reliable control of the air/fuel ratio. Second, they feature an advanced solenoid-actuated fuel valve that operates on a patented variable pressure control concept, taking input from the oxygen sensor. Lastly, they adopt a mixing venturi to replace traditional diaphragm/spring combinations, a feature that enhances performance by enabling the engine to run leaner before reaching a lean misfire condition. These electronic gas carburetors (EGCs) can be applied in various modes, including rich burn, stoichiometric, and lean-burn applications, thus enhancing overall performance and minimizing exhaust emissions. The EGC 2 model is designed for engines up to 250 hp, while the EGC 4 is tailored for engines up to 500 hp, with the potential of dual EGC 4 configurations for engines up to 1000 hp. Through extensive testing, these carburetors have demonstrated remarkable fuel savings and compliance with emissions standards in diverse applications.