We are thrilled to announce that Continental Controls Corporation (CCC) will be a part of the highly anticipated 29th GCA Annual Expo & Conference, running from Monday, March 25th to Thursday, March 28th! Join us at Booth 606 and 607 for a firsthand look at our latest innovations and solutions. Make sure to mark your calendars for President Dave Fisher's exclusive presentation...

Part #: 52000008

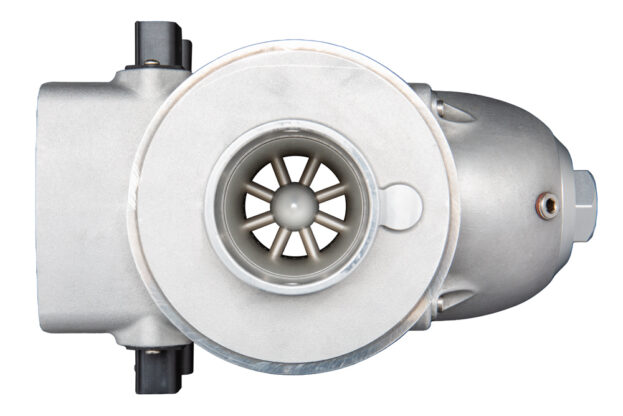

Electronic Gas Carburetor for Air-Fuel Ratio Control and Improved Gas Mixing

Call us for the latest pricing

Continental Controls offers a very innovative and state of the art approach to Gaseous Fuel Carburetion for most gas engines in the range of 10 to 500 horsepower. The Electronic Gas Carburetor (EGC) precisely controls the air/fuel ratio using variable pressure control combined with an advanced and improved mixing venturi.

- Provides innovative built-in control for a Wide-band Oxygen sensor that is located in the exhaust stream

- Improves control and enhances fuel mixing to reduce emissions and improve engine fuel efficiency

- Can be integrated with various communication protocols for remote monitoring and control

- Compatible with various gas fuels including natural gas, biogas, landfill gas, and more

- Offers advanced features such as closed-loop air/fuel ratio control and knock detection

- Helps optimize engine performance and reduce emissions

- Versatile and adaptable for a wide range of applications

- Energy efficient with low power consumption

- Provides accurate and reliable gas engine control

- Easy to install, program, and maintain

Product Weight (lbs): 21

Length (Inches): 16

Width (Inches): 10

Height (Inches): 10