This article underscores the growing importance of actively managing gas turbine fuel control, driven by factors like emissions compliance, plant efficiency, and operational longevity. It stresses the urgent need for operators to update their fuel systems and outlines five compelling reasons for doing so.

Aging components result in unreliable performance, necessitating constant intervention for stabilization. Modern turbomachinery demands swift responsiveness, prompting fuel control systems to align with these demands. Shifting workforce dynamics call for consolidated, automated fuel systems to ease the load on less-experienced personnel.

Evolving safety standards require robust, redundant, and instantaneous fuel control mechanisms. Inefficient fuel systems impact economics and profitability, making precise control offered by modern systems essential.

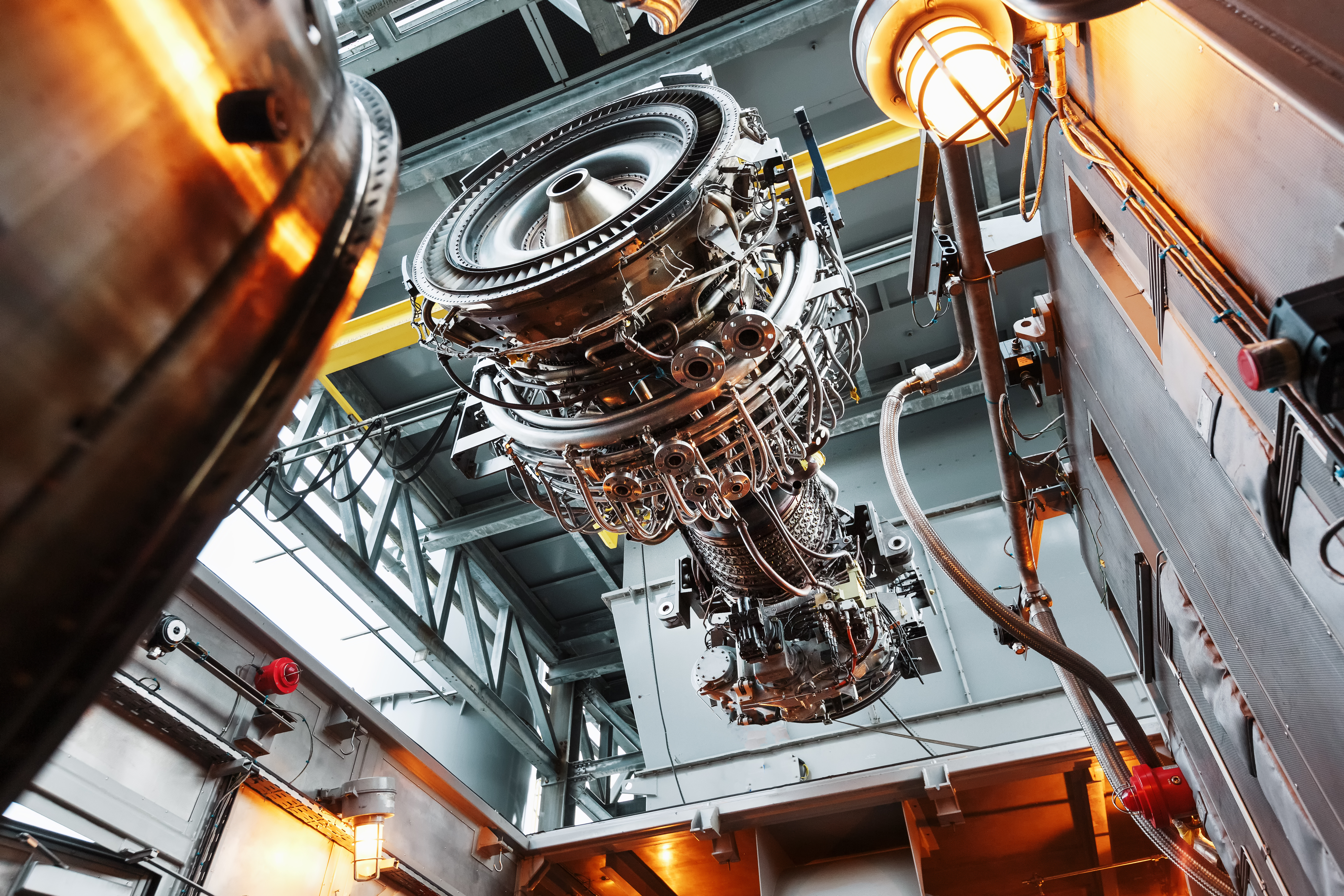

Highlighted as a transformative solution, the Gas Fuel Shutoff and Control System by Continental Controls seamlessly integrates various components for streamlined precision control, operational assurance, and compliance with contemporary standards. It is a recommended choice for operators seeking to revamp or replace fuel systems in gas turbines up to 50 MW.