Continental Controls Corporation (CCC) will be a part of the annual GMC Conference, October 6 to 9 in Tampa, FL. Educational sessions and presentations on recent GMRC research are valuable for design engineers, facility engineers, technicians and others. Join us at Booth 1025 for a firsthand look at our latest fuel product innovations and solutions. Make sure to also mark your calendars...

Used for integrating Air Fuel Ratio Controls (AFRC) and catalysts for Gas Engines

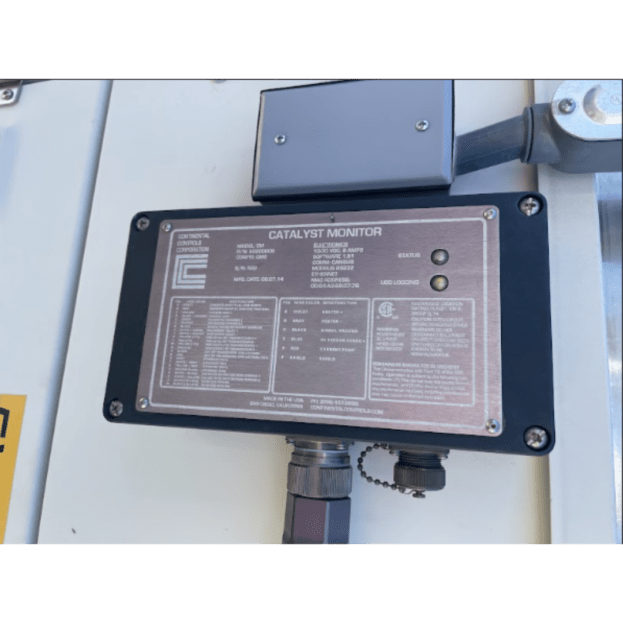

CCC technology is the key to integrating Air Fuel Ratio Controls (AFRC) and catalysts for Gas Engines. The CCC Catalyst Monitor is the central communication hub for various inputs and outputs for NSCR and Oxidation catalysts that doubles assurance that these devices were working as designed. The CCC Catalyst Monitor provides this function and is available in two versions: Data Logging (CMI) and Emission Control System (CM2-Single/CM3 Dual). The Catalyst Monitor solutions provide a comprehensive and intelligent approach to optimize air-fuel ratio control, catalyst performance, and emission reduction in Gas Engines.

- Parameter monitoring for national or local regulations

- Monitors key catalyst operating parameters

- Alarm or shut down on temperature or pressure

- Data logging on board for periodic or continuous download or retrieval

- Automatic adjustment to CCC AFR valves

- Operator configurable

- Variety of I/O supported options

- Non-resettable real time clock

Get a free quote