We are thrilled to announce that Continental Controls Corporation (CCC) will be a part of the highly anticipated 29th GCA Annual Expo & Conference, running from Monday, March 25th to Thursday, March 28th! Join us at Booth 606 and 607 for a firsthand look at our latest innovations and solutions. Make sure to mark your calendars for President Dave Fisher's exclusive presentation...

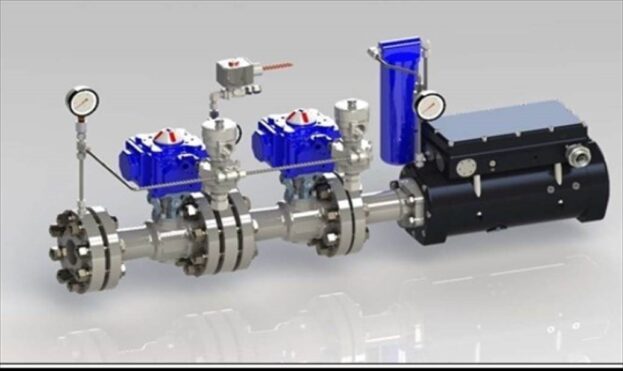

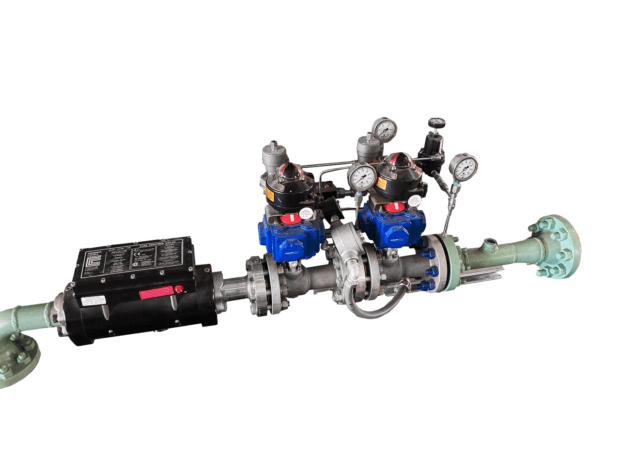

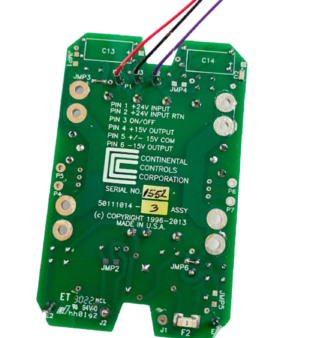

Part #: 50209718

Gas Fuel Train with 2” Valves

Call us for the latest pricing

The FT50 is specifically designed for use as a fuel shut-off component with Gas Turbine Engines.

- Pre-assembled and pressure-tested stainless steel piping and tubing

- Fail Safe Rapid closure in less than 200 milliseconds

- Equipped with a spring return for fail-safe operation

- Meets Safety Integrity Level (SIL) 2 to 3 standards

- Includes a vent valve for block and bleed functionality

- Provides superior shutoff performance exceeding class VI standards

- Designed to operate from line pressure

Product Weight (lbs): 200

Length (Inches): 30

Width (Inches): 30

Height (Inches): 30