Continental Controls Corporation (CCC) will be a part of the annual GMC Conference, rescheduled to 12 to 15 January in Houston, TX. Educational sessions and presentations on recent GMRC research are valuable for design engineers, facility engineers, technicians and others. Join us at Booth 1025 for a firsthand look at our latest fuel product innovations and solutions. Make sure to also mark...

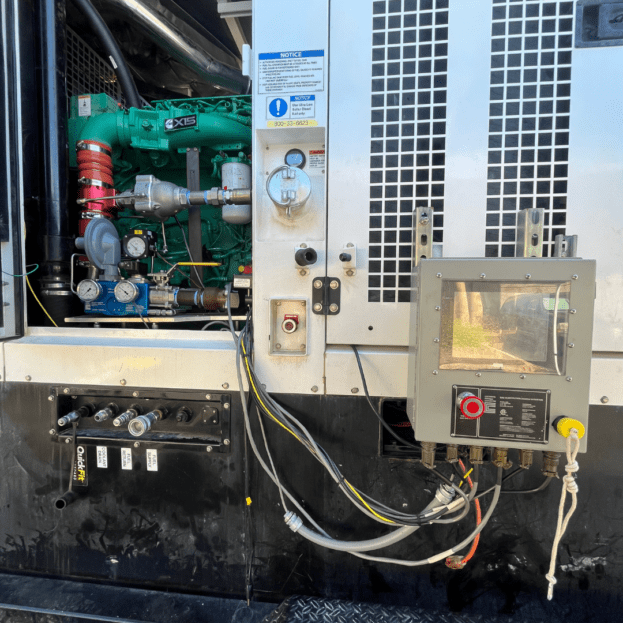

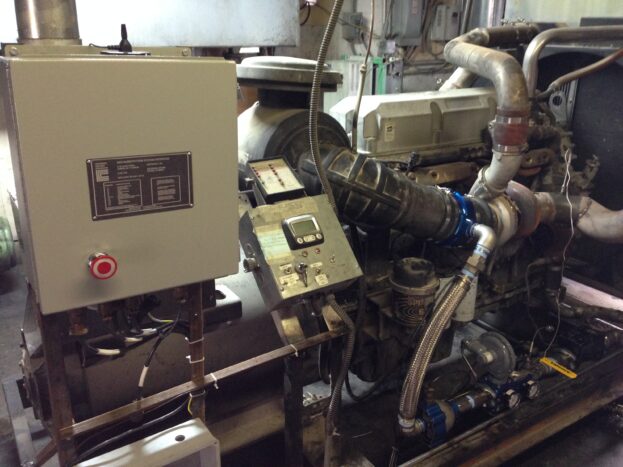

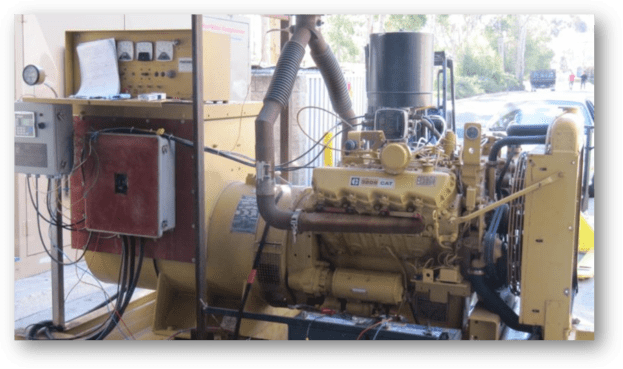

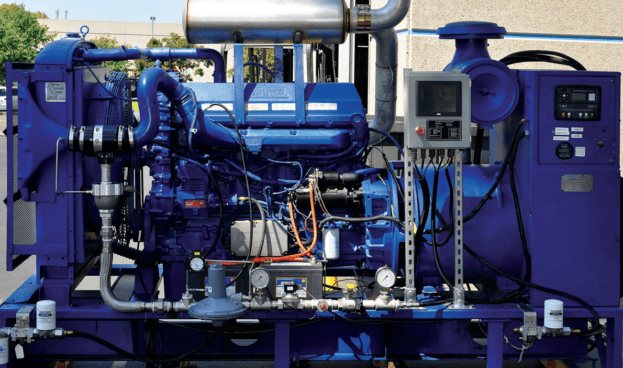

Gas Substituting System used on Diesel engines (no ignition system needed)

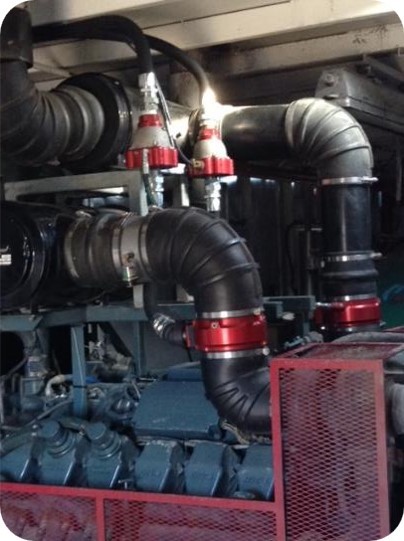

The GSS harnesses CCC’s leading fuel control technologies to substitute natural for diesel through the air stream on traditional diesel engines. Advanced substitution control is achieved through direct interface between the GSS and Engine Control Unit (ECU). At nearly any load condition and application, the GSS substitutes the maximum amount of diesel without sacrificing engine performance or power output. The GSS uses proven technology that has been field-tested with years of successful performance.

- Substitutes low-cost natural gas for diesel

- Daily average diesel fuel savings ~ $5,000/day*

- No internal engine modifications

- Lower emissions

- Simple installation

- Various systems for all sizes of diesel engines

- Optional gas flow meter displays totalized fuel savings

- Variable fuel control valve for increased AFR authority

- Substitution based on specific fuel consumption

- Substitution available at almost all loads

- Shut down from vibrations or temperature protect the engine from damage

- No decrease in power or engine performance

*Based on average U.S. Federal Diesel and Natural Gas pricing at 70% gas substitution

Get a free quoteDescription

Description

Continental Controls Corporation's Gas Substitution System (GSS) is an innovative product that allows diesel engines to operate on a combination of natural gas and other low-cost gases, such as biogas, landfill gas, or digester gas with traditional diesel fuel. The GSS system is designed to provide reliable and efficient combustion control for these blended gases while maximizing fuel savings and minimizing environmental impact.

The GSS system features specialized control panels and software to monitor and automatically adjust the combustion process in real-time to ensure optimal performance and stability. The system is also equipped with advanced safety features, such as shutdown systems and flame detection to prevent any potential hazards.

The use of low-cost gases in combination with natural gas offers several benefits. It can significantly reduce the operational costs of fueling gas engines in the magnitude of thousands of dollars per day. Additionally, the use of low-cost gases can reduce greenhouse gas emissions, helping industries meet their sustainability goals.

The GSS system is particularly beneficial for industries that generate significant amounts of waste gases, such as wastewater treatment plants, landfills, and agricultural facilities. By using waste gases in place of traditional fuels, these industries can reduce their environmental impact while also generating cost savings.

The Gas Substitution System utilizes cutting-edge technology to offer reliable and efficient combustion control in order to maximize cost savings and minimize environmental benefits.